The Manufacturing Process

Creating wood chair spindles involves a series of steps that transform raw wood into elegant and functional components. The process can vary depending on the desired style, scale, and production volume. However, common steps and methods are used to ensure quality and consistency.

Spindle Production Methods

The method of spindle production influences the final product’s quality, cost, and design possibilities.

- Hand-Turning: This traditional method involves using a hand-held woodturning lathe and chisels to shape the spindle. Hand-turning allows for intricate designs and unique finishes, making it ideal for custom or limited-edition pieces. However, it’s a time-consuming process requiring skilled artisans.

- Lathe Work: Lathes, powered by electricity or a motor, are used to rotate the wood stock while cutting tools shape the spindle. This method is faster and more efficient than hand-turning, allowing for greater production volume. Lathes can be used for both simple and complex spindle designs.

- CNC Machining: Computer numerical control (CNC) machining uses a computer to guide cutting tools with high precision. This method allows for complex shapes and high-volume production, making it ideal for mass-produced furniture. CNC machining offers repeatability and consistency, minimizing human error.

Tools and Equipment

The tools and equipment used in spindle production vary depending on the chosen method.

- Hand-Turning: Hand-turning requires basic tools like a woodturning lathe, chisels, calipers, and sandpaper. The lathe provides the rotation, while chisels shape the wood. Calipers measure dimensions, and sandpaper smooths the surface.

- Lathe Work: Lathes are equipped with a chuck to hold the wood, a motor to power the rotation, and a tool rest to support the cutting tools. Different types of lathes exist, including woodturning lathes, metal lathes, and combination lathes. Cutting tools include chisels, gouges, and parting tools.

- CNC Machining: CNC machines use computer programs to control the movement of cutting tools, such as end mills and drills. The machines are equipped with a spindle to rotate the tools, a table to hold the wood stock, and a control panel to program the machine.

Quality Control and Finishing Techniques

Quality control is essential throughout the spindle production process to ensure consistent quality and durability.

- Inspection: Spindles are inspected at various stages, including after cutting, sanding, and finishing. This ensures that the spindles meet the required dimensions, have no defects, and are free from burrs or imperfections.

- Finishing: Finishing techniques enhance the appearance and durability of the spindles. Common finishing techniques include sanding, staining, painting, and varnishing. Sanding smooths the surface, while stains and paints add color and protection. Varnishes provide a durable, protective coating.

Applications and Uses: Wood Chair Spindles Parts

Wood chair spindles are versatile elements that contribute significantly to both the aesthetic appeal and structural integrity of chairs. They are found in a wide array of chair styles, enhancing their visual impact and providing crucial support.

Chair Styles Utilizing Spindles

Spindles are commonly incorporated into various chair styles, each showcasing unique designs and functionalities. Here are some examples:

- Windsor Chairs: Known for their distinctive, turned spindles that form the back and often the seat supports. The spindles are typically arranged in a radial pattern, creating a visually appealing and sturdy structure.

- Ladderback Chairs: These chairs feature vertical spindles, resembling rungs on a ladder, that are connected to a top rail. This design provides both visual interest and structural support for the back.

- Slat-Back Chairs: These chairs often utilize spindles as decorative elements, adding visual appeal to the back slats. Spindles can be placed between the slats, creating a lattice-like effect.

- Turned Leg Chairs: Spindles are commonly used in turned legs, providing both aesthetic appeal and structural support. They can be turned in various shapes and sizes, adding visual interest to the chair’s base.

The Role of Spindles in Chair Aesthetics and Functionality, Wood chair spindles parts

Spindles play a crucial role in shaping the aesthetics and functionality of chairs. They contribute to:

- Visual Appeal: Spindles can be turned in various shapes and sizes, adding intricate details and visual interest to the chair. They can be carved, painted, or stained, further enhancing their aesthetic appeal.

- Structural Support: Spindles provide essential support for the back, seat, and legs of the chair, ensuring stability and durability. They distribute weight evenly, preventing the chair from collapsing or becoming unstable.

- Comfort: The spacing and arrangement of spindles can influence the comfort of a chair. Spindles can provide back support, creating a more comfortable sitting experience.

Spindle Configurations and Their Impact on Chair Design

Spindle configurations play a significant role in defining the style and functionality of a chair. Different configurations can create unique visual effects and influence the chair’s overall design.

- Radial Spindles: Commonly found in Windsor chairs, radial spindles radiate from a central point, creating a visually appealing and structurally sound design.

- Vertical Spindles: These spindles are arranged vertically, creating a ladder-like effect. They are often used in ladderback chairs, providing both visual interest and structural support.

- Horizontal Spindles: These spindles are arranged horizontally, often used as decorative elements in slat-back chairs or as structural elements in the seat frame.

- Combined Configurations: Many chair designs incorporate a combination of spindle configurations, creating unique and visually appealing designs.

Spindle Use in Other Furniture Pieces

Spindles are not limited to chair design; they are also commonly used in other furniture pieces, adding both aesthetic appeal and structural support.

- Beds: Spindles are often used in bed frames, particularly in headboard and footboard designs. They can be turned in various shapes and sizes, adding visual interest and creating a decorative element.

- Tables: Spindles can be incorporated into table legs, adding visual interest and providing structural support. They can also be used as decorative elements in table aprons or rails.

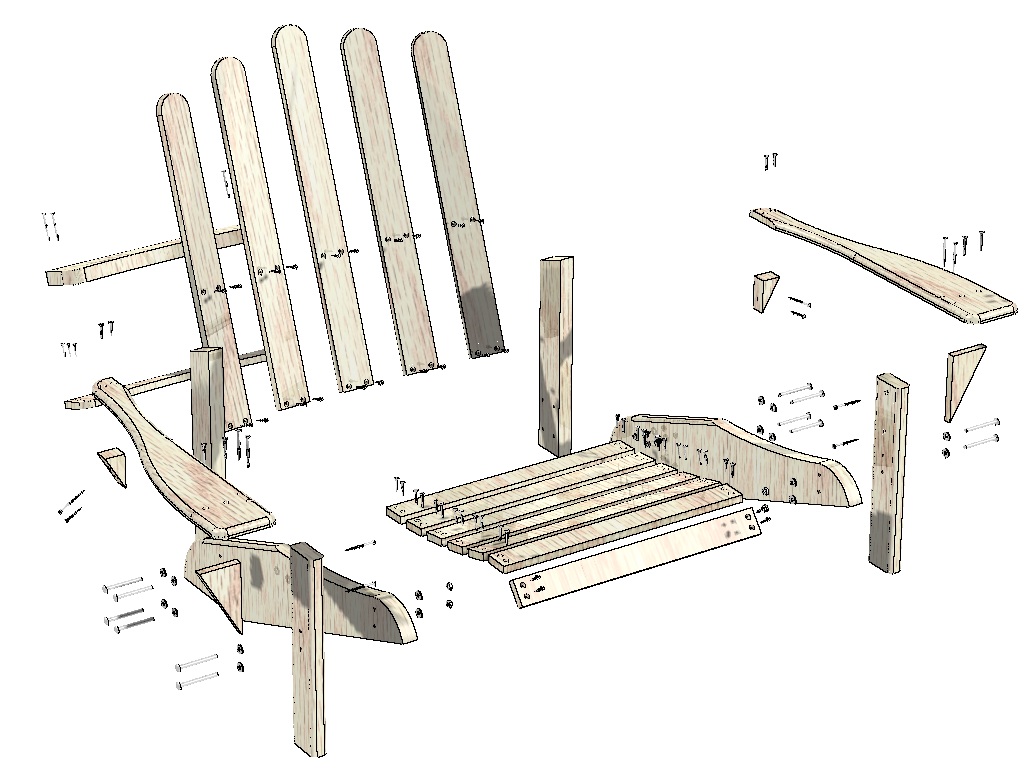

Wood chair spindles parts – You know, those wood chair spindle parts are proper fiddly, ain’t they? Like trying to build a whole chair out of matchsticks. But if you’re going for something big, like a giant wooden lawn chair , then you’re gonna need some serious spindle action.

That’s where the real craftsmanship comes in, man. Proper scale, you know what I mean?

Wood chair spindles are a classic design feature, adding a touch of elegance and character to any chair. They’re also surprisingly versatile, with different styles and shapes to suit any taste. If you’re looking to add a touch of sophistication to your walls, consider adding a wood trim chair rail – it’s a great way to add a touch of classic charm.

And when it comes to wood spindles, there’s a whole world of possibilities out there, from simple turned spindles to intricate carved designs.